Manufacturing

We print in

PLA (composites), PETG, HIPS, ABS, TPE/U Nylon und Natur

PLA stands for Polylactide Acid (mold stability up to 50 – 60°C). The standard for plastic prototype parts from the 3D printer.

ABS stands for Acrylonitrile butadiene styrene copolymer (deformation from approx. 80°C) A plastic that has been proven to have high technical resilience

TPE/U stands for Thermoplastic Elastomers / Urethanes. The sealing plastics also have a technical requirement and are used in many areas.

Nylon or PA (polyamide) is also one of the more resilient plastics.

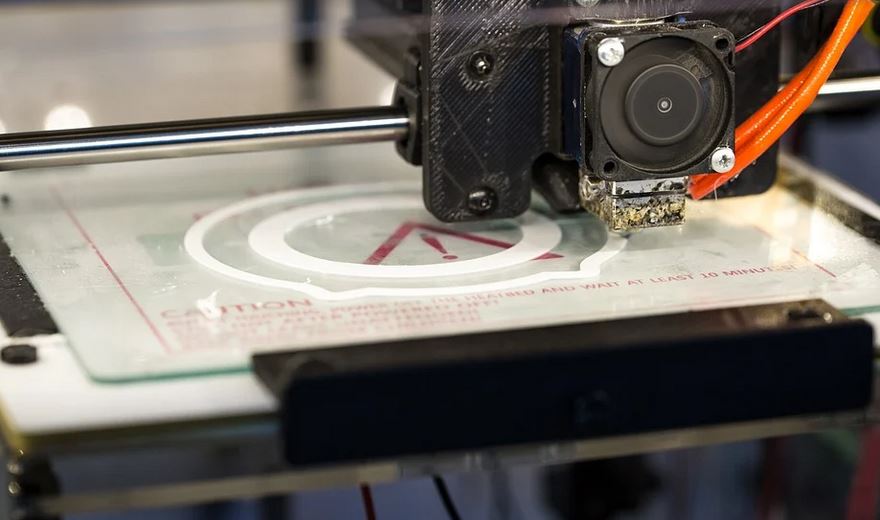

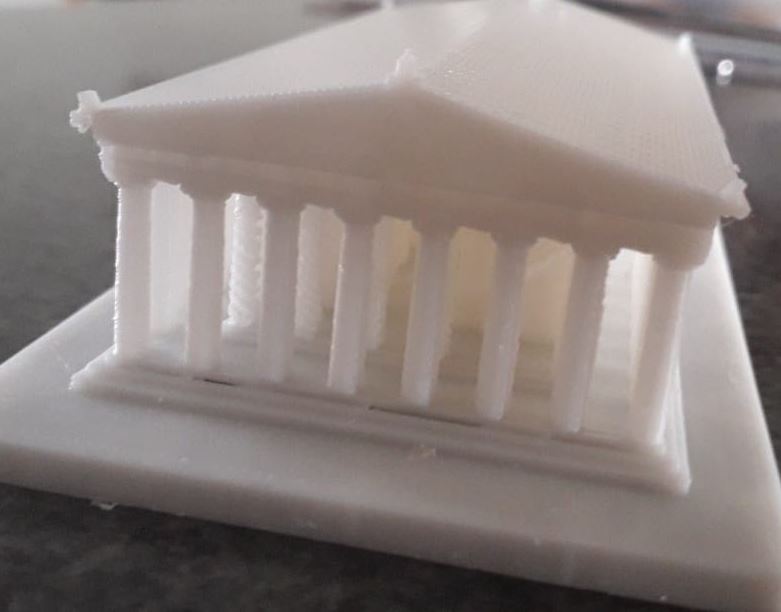

We are active in the production of prototypes and small series. We support your development in the prototypeing phase

Plastic development:

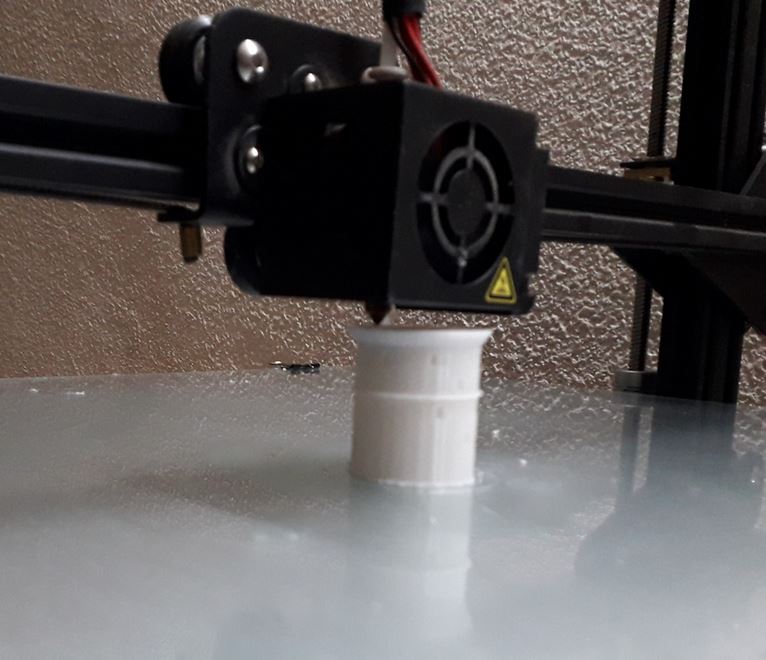

3D printed parts based on filament manufacturing (e.g. PLA, ABS, Nylon). On request we can also produce RESIN parts.

Prototype parts are used to validate the development status of a construction phase. Many companies use the knowledge gained from rendered or constructed components in order to save costs. With this knowledge, the quality of the product can be increased and optimized.

We also manufacture 3D printed parts for private and personal use. Several databases are available and free. The platforms thingiverse and stlfinder are well-known portals for private usage

Mold making:

We also produce molds or small series components from different materials.

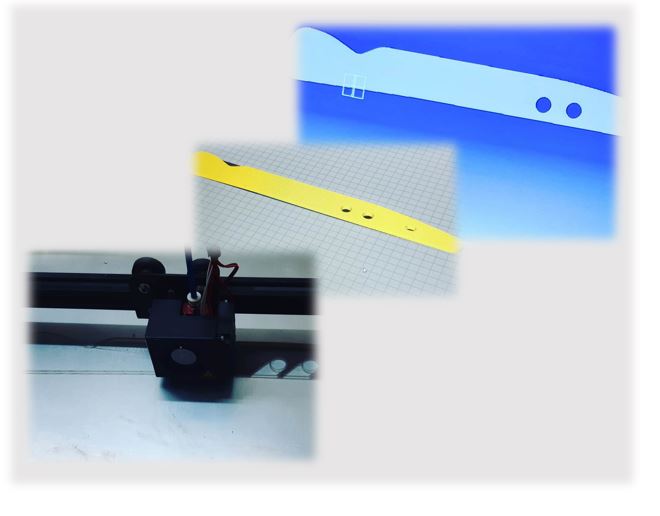

3D milled parts for e.g. wood or aluminum (3-axis / 2.5-axis control) are common practice.

The area of application is diverse, from samples or fully constructed components to reversed products. Some products are not available in the automotive sector (oldtimers).

Hybrid construction empowers a combination of plastic components, as well as the use of metals and other materials for an overall product.

Some of our customers often ask how the price is related to quality. There are good prototype builders on the market and they all start with the same questions: What use is the component be expected to have? What accuracy should the component have and when should it be delivered? Of course, there are also other “W” questions.

It can be assumed that a direct dependency on the accuracy of the component (tolerances), the ability to deliver (use) and the mechanical and structural integrity (material) are decisive for the increased costs of a product.

Together we define the specifications and take the time to examine the request and the specifications in the team as part of the development.